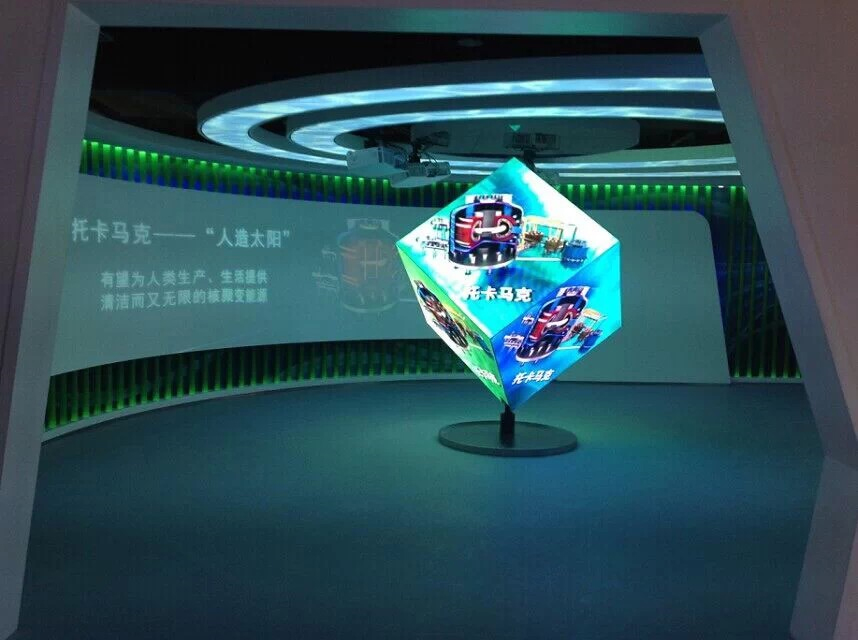

DIP, SMD two kinds of common outdoor LED display package

In the production process of full color LED display, packaging is very important a ring, now, on the market have 2 kinds of outdoor LED display screen is packaged in a manner: dip, SMD.

We know the role of the package is lead is connected to the electrodes of the LED chip, and protect the LED chip, and played a role in improving the luminous efficiency, good packaging can make LED has better luminous efficiency and thermal environment, and enhance the LED life.

.DIP package

DIP packaging, is the inline-pin package dual abbreviation, commonly known as plug-in display. Is the first developed in the three packaging models. Lamp beads are produced by the LED lamp packaging manufacturers, by the LED module and display manufacturers will ed into the led the PCB lamp panel, through wave welding produce dip semi outdoor module and outdoor waterproof module. At the beginning of the red, green and blue three colors of lights in on the PCB composition a RGB pixels, the latter can already the RGB three chip package in a light bead, namely triple a outdoor full color, relatively improve the production efficiency and production cost. But no matter single RGB light or triple RGB are spacing is subject to the diameter of the lamp, at present can only do P6, it is difficult to achieve higher density of outdoor display. Good protection performance, but the angle of view is not good precision fixed, generally in the 100-110, so it is suitable for outdoor large screen.

DIP displays the current view, the production organization is more complex, not easy to implement mechanized production, production efficiency. The quality of subject display beads beads package factory in quality, each batch of good control, so the quality is not good stability control. Also dip many manufacturers, there is no very high threshold technology and equipment, fierce competition, many manufacturers use inferior raw materials and PCB board, reduce the cost to gain market share, the quality is low, almost no perfect after-sale guarantee.

Dip products from the appearance of the relatively rough, angle of view only 100-110 degrees, quality is not high, high energy consumption, environmental protection, low price, at present in outdoor P20-P8 market but also to occupy a strong market share.

Two.SMD package

SMD package is the abbreviation of surface mounted devices, meaning: surface mount device, it is SMT (Surface Mount Technology Chinese: SMT components. "In the primary stage of the electronic circuit board production, the hole assembly is completely finished by the manual. After the introduction of the first automatic machine, they can be placed in a number of simple pin elements, but the complex components still need to be manually placed in the wave soldering. Surface mount components in about twenty years ago to launch, and thus creating a new era. From the passive components to the active components and integrated circuits, and eventually become a surface mount device (SMD) and can be assembled by the pick up device. In a very long time people think that all of the pin components can be used in the SMD package. SMD technology is widely used in LED display.

Three is a kind of display LED SMD technology, is refers to the RGB three different colors of LED chip package, SMT lamp according to a certain pitch package in a colloid. The triple a SMD technology for full-color LED display full screen view relative dip is larger, and the surface can be do light diffuse reflection treatment. Results no granular, color uniformity is good. From the color of speaking, three in one color spectrophotometer is an easy three spell, and high color saturation. The three one is to use the whole surface to shine, so the three one is more uniform on the whole. Three in the overall smoothness of the more easy to control. Has been the use of high-definition LED display standard technology.

Early development, because the manufacturing process is complex, maintenance difficulties, resulting in high cost, generally used for high-end LED display products. In recent years the triple technology rapid development and production process of continuous improvement, the extensive use of automated equipment, SMD development rapid, reducing the cost of many, is currently the mainstream product of indoor LED display screen. And has begun to penetrate the outdoor display market, but the brightness and outdoor waterproof, moisture, dust, anti-static, oxidation has been its insurmountable gap.